ESD-Checklist

All ESD protective measures have to be controlled and documented regularly. The following list contains fundamental questions that have to be observed during the auditing process.

In general

ESD representative:

- Is there an ESD representative?

- Is there a substitute for the ESD representative?

- Has the ESD representative received adequate training?

- Does the ESD representative control and verify the ESD protections regularly?

- Do internal audits take place regularly?

Training:

- Are there trainings for the personnel?

- Are there refresher trainings?

- Do you provide training for new personnel upon recruitment?

ESD-Control plan

- Is there a control plan according to IEC 61340-5-1?

- Are suitable limit values defined for voltage potentials, resistance values, etc.?

- Does your control plan include information about the chosen grounding system and grounding method?

- Is it specified how your ESD components are to be handled during storage and transport?

- Are the employees sufficiently trained on the control plan?

- Is the control plan regularly reviewed and updated?

Personnel grounding

Wriststraps:

- Are wriststraps and cables checked every day?

- Is the check documented?

- Are there replacement wriststraps?

- Do you replace wriststraps and cables that do not work any longer?

Shoes:

- Are the shoes checked every day?

- Is the check documented?

- Are there sufficient heel grounders for visitors?

Clothes:

- Do you use ESD-compliant clothes?

- Are the ESD-compliant clothes checked and replaced regularly?

- Are there sufficient work coats for visitors?

Measurement and test equipment

Test equipment:

- Is there any test equipment for checking wriststraps?

- Is there any test equipment for checking shoes?

- Is the test equipment calibrated?

- Are there checklists for countersigning?

Measurement equipment:

- Is there a contact resistance meter and a hygrometer?

- Are there appropriate measuring electrodes?

ESD protective equipment

ESD protected areas (EPA):

- Are there any defined ESD protected areas (EPA)?

- Are the ESD protected areas marked?

Floor:

- Is the floor dissipative?

- Is the cleaner you use suitable for ESD floors? Do you use any waxes etc. leaving no residues?

- Are the dissipative properties of the floor checked regularly?

Tables/shelves/workstations:

- Are the table and shelf surfaces dissipative?

- Is there a possibility to connect wriststraps?

- Are the grounding terminals marked?

- Are tables and shelves grounded?

- Have all materials been removed from the workstations that might cause electrostatic charges?

Chairs:

- Are the chairs dissipative?

Racks:

- Are the rack surfaces dissipative?

- Are the racks grounded?

Transport trolleys:

- Are the transport trolleys dissipative?

- Are the dissipative properties of the transport trolleys checked regularly?

Containers:

- Are the containers dissipative?

- Are the containers marked?

Other materials:

- Are other materials dissipative of antistatic?

Tools

- Are the tools ESD-compliant?

- Do the soldering stations have an ESD grounding terminal and is this connected to a grounding connection point?

Cleaning:

- Are all surfaces and floors regularly cleaned with ESD cleaners?

- Is the cleaning staff adequately trained?

- Are ESD textiles washed regularly?

- Are all components of an EPA regularly checked after cleaning according to the control plan?

Packaging

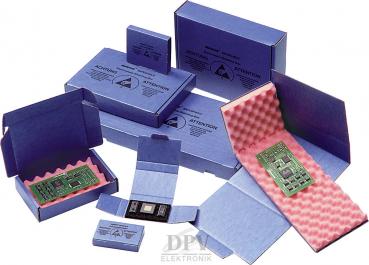

- Are ESDS transported in ESD-compliant packaging and containers?

- Are there any ESDS in ESD-compliant material if they are transported and stored in an uncontrolled environment?

- Has the package shielding properties if the ESDS are transported from one ESD area to another?

- Are all components, even not ESDS, packed in ESD-compliant material if they are in an EPA?

- Is ESD-compliant material marked if it contains ESD-sensitive devices?

- Has the packaging material been checked?

Good receipt

- Are the supplied ESD-sensitive devices in ESD-compliant transport containers?

- Do the accompanying documents contain any information concerning ESD-sensitive devices?

- Is the information sufficient for the personnel to identify ESD-sensitive devices?

- Is the handling of ESD-sensitive devices without protective outer package reduced to a minimum?

- Is the package of the ESD-sensitive devices opened at an ESD-protected workstation?

- Has the personnel working in the goods receipt department been trained in handling ESD-sensitive devices?

- Are ESD-sensitive devices packed in ESD-compliant packaging when leaving the ESD workstation and are they properly marked?

Other measures

- Are there any materials generating electrostatic charge (e.g. cases, assembly parts) and are there any measures for reducing electrostatic charge?

- Are devices and machines (monitors etc.) set up at sufficient distance to ESDS (>1m)?

- Are working instructions and documents stored in ESD-compliant films or film holders?

All protective measures listed are compiled in our checklist – download now!

All protective measures listed are compiled in our checklist – download now!ESD protected area

Wherever people move or material is moved, electrostatic charge is generated. Electronic assemblies with an increasingly smaller structure can be damaged or destroyed by electrostatic discharge. As electrostatic charge cannot be felt or easily measured with a multimeter, these risks have to be assessed professionally.

The components damaged by electrostatic discharge can lead to a failure or a shortened service life of the affected assemblies. In order to prevent electrostatic charge of people and material, ESD protection measures are required. The aim is to prevent charge by grounding and slowly discharge charged material.

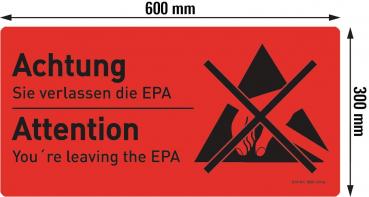

Areas designed in such a way that electronic assemblies can be handled safely are referred to as ESD protected zones or EPA (Electrostatic Protected Area).

These areas are specially marked.

Regardless of the equipment of the ESD protection zone, additional measures must be observed:

- ESD-sensitive components (ESDS) may only be processed in the ESD protection zone (EPA)

- Ensure personal grounding via wrist strap and ESD shoes

- Wear dissipative clothing covering other clothes

- Avoid electrostatically chargeable materials such as PE, PVC, polystyrene etc.

- Electrostatic fields of > 5000 volts/m have to be avoided

- Use only labelled ESD packaging and transport containers

- Only ESD-trained personnel may be employed in EPA protection zones

Regular monitoring of the protective functions in the EPA ensures safe processing of electronics.

Floor marking

Floor markings are used to mark an ESD area.

Floor covering

ESD floors are special floor coverings that prevent the electrostatic charge and discharge and instead direct the electrostatic charge to a grounding point.

Wastebasket / waste container

ESD wastebaskets / waste containers are used to dispose of the garbage in ESD areas.

Wastebasket / waste container

ESD wastebaskets / waste containers are used to dispose of the garbage in ESD areas.

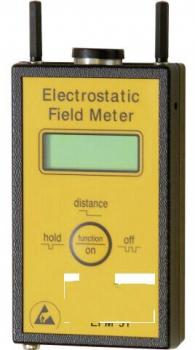

Measuring and testing equipment

Measuring and testing devices are available in various designs, are used to measure and log e.g. surface resistances, discharge values, charge/discharge in EPA zones.

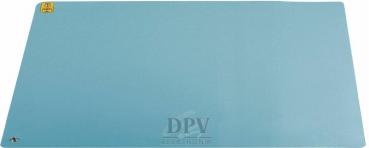

Table coverings

Available in different colors / standard dimensions and on request in customer-specific specifications. Dimensions and designs / electrostatically conductive and dissipative properties / protects people and components through gentle discharge.

Table coverings

Available in different colors / standard dimensions and on request in customer-specific specifications. Dimensions and designs / electrostatically conductive and dissipative properties / protects people and components through gentle discharge.

Grounding box

Grounding boxes are necessary to ground wrist straps, table coverings, grounding cables.

Grounding box

Grounding boxes are necessary to ground wrist straps, table coverings, grounding cables.

Grounding box

Grounding boxes are necessary to ground wrist straps, table coverings, grounding cables.

Ionizer

Ionizers neutralize electrostatic charges at workstations and in the service area as well as in machines such as pick-and-place machines.

Ionizer

Ionizers neutralize electrostatic charges at workstations and in the service area as well as in machines such as pick-and-place machines.

Flooring cleaner

Thorough floor cleaning for normally and very heavily soiled ESD floors.

Tablecloth cleaner

Cleaning for conductive surfaces in the ESD area (table coverings).

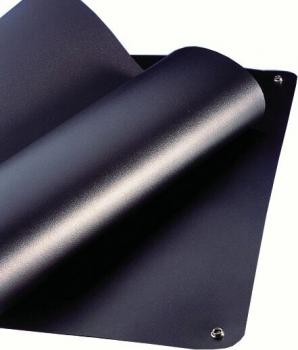

Shelf coverings

Volume-conductive ESD shelf covering for shelves, tool benches, transport trolleys (protection of components).

Ring folders / document protectors

Dissipative folders and document protectors for keeping documents in an EPA.

Containers

For the transport and storage of electronic components, as protection against damage caused by electrostatic discharges.

Personal test station

Measuring device for verification, measurement, documentation, logging of personal grounding of employees / visitors.

Warning signs

Warning signs for the wall to identify an ESD workstation.

Waring labels

For marking / labeling of ESD endangered bags / products on packaging / bags.

Permanent monitoring

Permanent monitoring of ESD events at workstations, machines, tools ...

Shipping boxes

High shielding properties, for shipping, transport or storage of sensitive ESD components, can be equipped with various foams (option).

Wrist straps

A wrist strap is used to ground people and thus prevent electrostatic discharge (ESD) / connection to table mats or grounding module.

Heel grounders / shoes

Wearing ESD shoes prevents the build-up of electrostatic charge in the body by dissipating the charge into the ground in a very safe and very controlled way. They guarantee the suppression of sudden electrical discharge between electrically charged objects upon contact.

Clothing

ESD clothing has to be worn in ESD protection zones. In contrast to the rest of the workwear, ESD clothing has woven conductive fibers that dissipate the electrostatic charge.

Film bags

ESD film bags are used as packaging for electronic devices or parts thereof to protect them from static electricity. Depending on the design, ESD bags offer protection against electrostatic charge or direct discharge and protect against dust and, in some cases, also against water vapor and gases.

Film bags

ESD film bags are used as packaging for electronic devices or parts thereof to protect them from static electricity. Depending on the design, ESD bags offer protection against electrostatic charge or direct discharge and protect against dust and, in some cases, also against water vapor and gases.

Grounding cable

Versions in various lengths and connections, is required, for example, for the connection from the wrist strap to the table mat / grounding plug / wrist strap / table mat.

Chairs

ESD chairs protect against electrostatic discharge, dirt particles and sparks. ESD chairs prevent charging or effectively dissipate it and prevent discharge when touching sensitive components.

PCB holders

Ideal for the intermediate storage / storage / transport of assembled and unequipped printed circuit boards in ESD production or test areas.