Colorex SD, ableitfähig

dpvlink 13997

Eigenschaften des Bodenbelags

Konstante Leitfähigkeit über die gesamte Lebensdauer

Die einzigartige Materialkonstruktion von Colorex SD gewährleistet eine konstante Leitfähigkeit über die gesamte Lebensdauer des Belages, unabhängig von Luftfeuchtigkeit und Temperatur. In Kombination mit geeignetem Schuhwerk leitet Colorex SD Ladungen sicher durch das Adernetz ab. Colorex SD leitet nicht nur die vom Menschen erzeugte Ladung sicher ab, sondern sorgt bereits an der Schnittstelle zwischen Schuhsohle und Fußboden für eine Verringerung der Ladung. Dieser Boden erfüllt alle ESD-Normen

Reinraumtauglichkeit

In Reinraum-Umgebungen der Mikroelektronik können bereits feinste Luftpartikel Verunreinigungen verursachen. Die Folgen sind Vorbeschädigungen und Eintragsbußen. Colorex SD erfüllt als hochverdichtetes Material mit porenfreier Oberfläche höchste Anforderungen an das Partikelemmissionsverhalten und trägt zur Reduzierung der Kontamination durch molekulare lufttragene Partikel bei.

Keim- und partikelfreie Oberfläche

Erfüllt höchste Hygieneanforderungen durch die antimikrobielle, kompakte und porenfreie Oberfläche. Außerdem zeichnet sich der Boden auch mit einer sehr guten Beständigkeit gegen Desinfektionsmittel aus.

Belastbar

Die hochdruckverpresste Konstruktion ist extrem strapazierfähig, beständig gegen hohe Punktbelastungen und resistent gegen statische und dynamische Lasten. Zudem besitzt er beste chemische Beständigkeit.100% sanierbar und reparierbar

Tiefe und lange Kratzer, Löcher sowie Verbrennungen lassen sich effektiv und spurlos entfernen, ohne die ursprünglichen Eigenschaften des Belages zu beeinträchtigen. Sichtbare Beschädigungen lassen sich durch thermische Material-in-Material-Verschweißung beheben. Dazu wird ein Streifen des gleichen Belagmaterials erhitzt und direkt in die Beschädigung eingearbeitet. Nach dem Abschleifen und Polieren des reparierten Bereichs entsteht wieder ein homogenes Erscheinungsbild. Gefährliche Verunreinigungen durch Radionuklide können rückstandsfrei entfernt werden.

Pflege und Werteerhalt

Lose aufliegender Schmutz kann durch Saugen oder feuchtes Wischen mit imprägnierten Einwegtüchern beseitigt werden. Alternativ kann der Boden mit einer Einscheibenmaschine mit rotem Pad und Sprühvorrichtung in Verbindung mit einer neutralen und wachsfreien Reinigungslösung spraygecleanert werden. Großflächen mit einer geeigneten Scheuersaugmaschine reinigen. Randbereiche manuell reinigen.

Colorex fängt dort an, wo andere aufhören

Colorex wird durch spezielle Produktionstechnik gefertigt. Dieses Verfahren verleiht dem Material eine extrem hohe und gleichmäßige Dichte.

Schritt 1: Zerkleinern und leitfähige Ummantelung

Die Bahnenware wird in einzelne, kleine sogenannte "Chips" geschnitten. Diese werden anschließend mit einer leitfähigen Substanz ummantelt.

Vorteil

- Konstante Leitfähigkeit über die gesamte Lebensdauer

- Die einzelnen beschichteten Chips arbeiten als "Leiterbahnen" und garantieren eine konstante Leitfähigkeit über die gesamte Lebensdauer des Belages, unabhängig von der Luftfeuchtigkeit und Temperatur.

Schritt 2: Hochdruckpressverfahren

Die leitfähigen Chips werden unter extrem hohem Druck und hoher Temperatur zu dicken Materialblöcken verpresst.

Vorteil

- Hochbelastbar

- Die mit Hochdruck verpressten Chips bilden eine perfekte, homogene Materialzusammensetzung, die problemlos und langfristig starken mechanischen und dynamischen Belastungen widersteht.

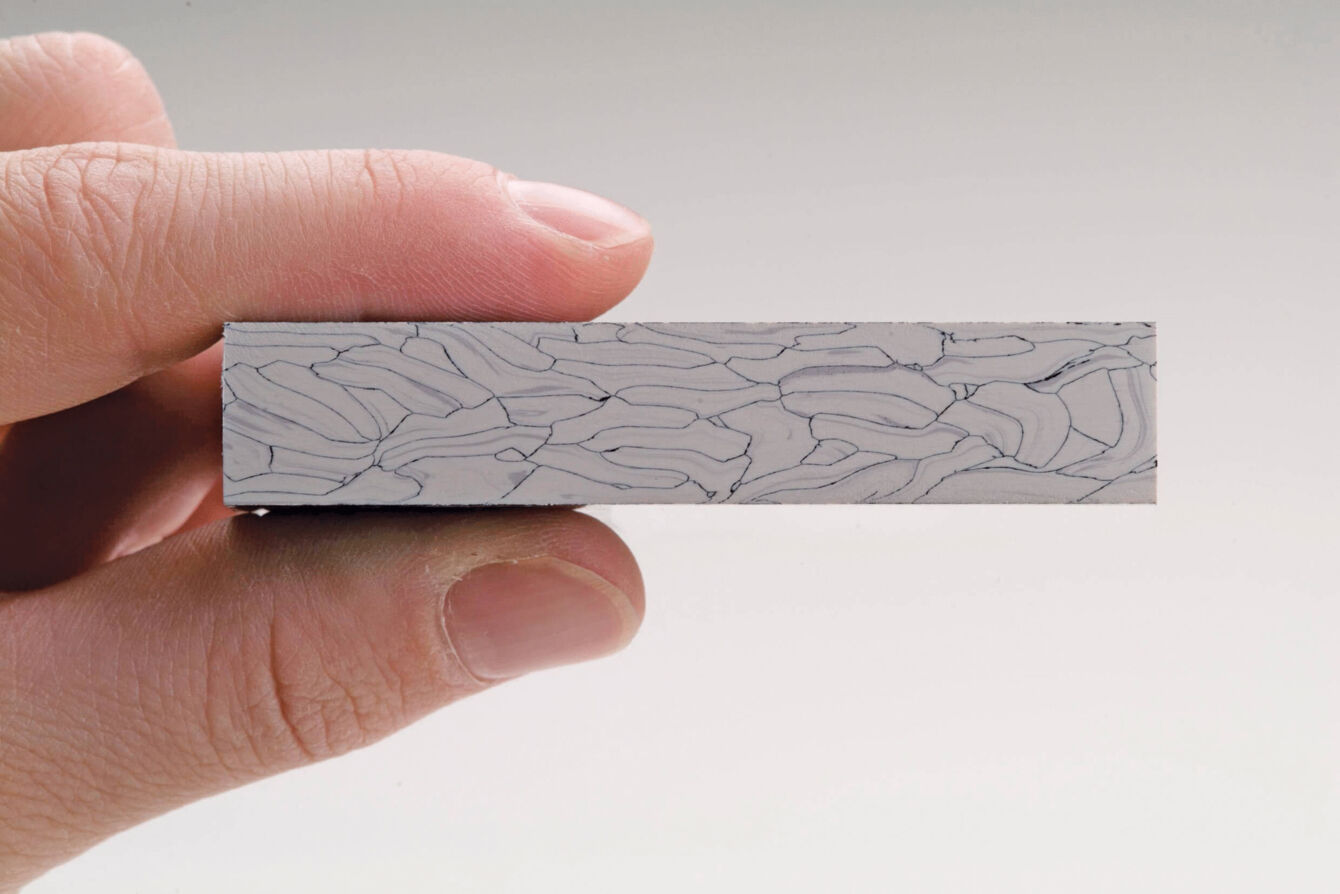

Schritt 3: Spaltung und mechanische Oberflächenbehandlung

Die homogenen, verpressten Blöcke werden anschließend in einzelne 2,0 mm dicke Platten geschnitten.

Vorteil

- Repratur-/ sanierfähig, chemikalienbeständig

- Das Schneiden der homogenen Platten ermöglicht eine vollständige Reperaturfähigkeit ohne optische und funktionale Beeinträchtigung des Bodens sowie - dank hochverdichteter Oberfläche - eine ausgezeichnete Chemikalienbeständigkeit

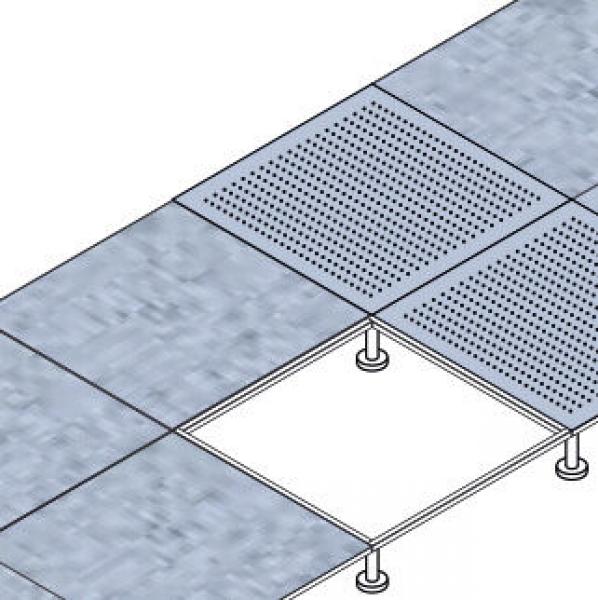

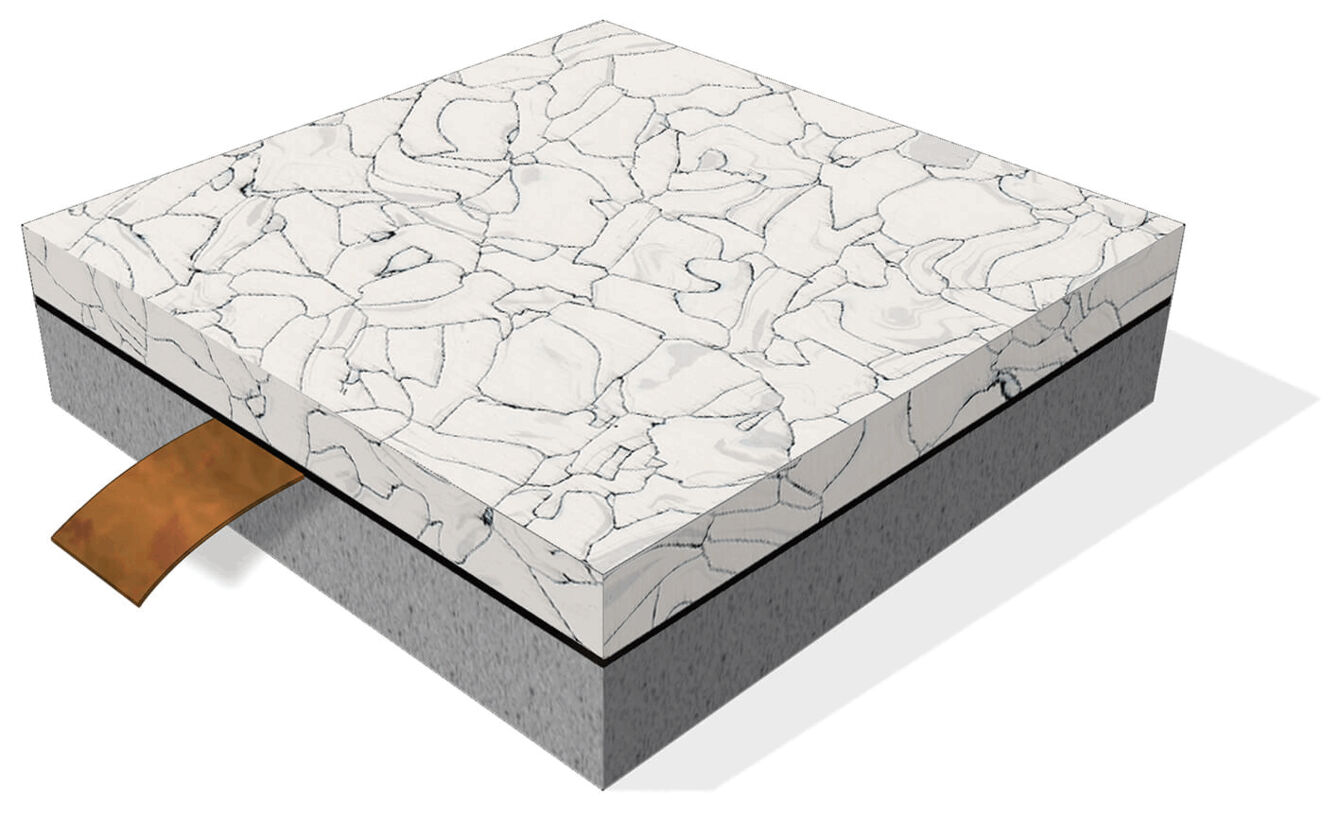

Colorex vollflächig verklebt

Durch eine leitfähige Verlegung wird garantiert, dass unerwünschte elektrostatische Ladungen durch das dichte Netzwerk an feinen leitfähigen Leiterbahnen durch die gesamte Plattenstärke hindurch abfließen können. Die Ladungen werden durch den leitfähigen Klebstoff und die Kupferstreifen sicher abgeleitet. Falls kein leitfähiger Boden erforderlich ist, kann Colorex auch mit normalem Klebstoff verlegt werden, als nicht leitfähige Variante. Um höchste hygienische Anforderungen zu erfüllen, wird empfohlen Colorex farbgleich thermisch zu verschweißen.

Technische Daten

CE-Zeichen | EN 14014 | Konform |

Oberfläche |

| Glatt |

Gesamtdicke | EN ISO 24346 | 2,0mm |

Gewerbe Klasse | EN ISO 10874 | 34 sehr stark |

Industrie Klasse | EN ISO 10874 | 43 stark |

Größe | EN ISO 24342 | 615 x 615 mm |

Fließengröße m2 |

| 0,3782 m² |

Flächengewicht | EN ISO 23997 | 3,2 kg/m² |

Brandverhalten | EN 13501-1 | Bfl -S1, L, CS |

Wärmeleitfähigkeit | EN 12524 | 0,25 W/(m·k) |

Rutschhemmung | DIN 51130 | R9 |

| bfu/bpa/upi R 9729 | GS1 |

Stuhlrollenbeanspruchung | ISO 4918 | geeignet Typ W |

Thermischer Dilatationskoeffizient |

| 0,07 mm/m°C |

Elektrischer Ableitwiderstand | IEC 61340-4-1 | 1 x 106 ≤ R ≤ 108 |

| ESD STM7.1 |

|

Elektrischer Systemwiderstand mit ESD-Schuhen | IEC 61340-4-5 | R ≤ 1 x 109 Ω |

| ESD STM97.1 |

|

Begehaufladung mit ESD-Schuhen (Typischer Wert) | IEC 61340-4-5 | < 100 V ~ 40 V |

| ESD STM97.2 |

|

Dimensionsstabilität | EN ISO 23999 | ≤ 0,05% |

Resteindruckverhalten (Typischer Wert) | EN ISO 24343-1 | ≤ 0,10 mm ~ 0,02 mm |

Trittschallverbesserung | EN ISO 140-8 | 2 dB |

Lichtechtheit | EN ISO 105-B02 | ≥ 6 |

Beständigkeit gegen Belastung | Hubwagen und Gabelstapler: Gesamtgewicht bis 2,5 t und mit Luftreifen 5 t; Statisch: 50kg/cm³ - Dynamisch 90 kg/cm³ | |

Chemikalieneinwirkung | EN ISO 26987 | Sehr gut |

Reinraum Emissionen | IDEMA M11-99 | total < 1 μg/cm2 |

Reinraum Partikelemission | IDEMA 14644-1 | ISO 4 |

Recyclinganteil | Bis zu 95% Recyclinganteil in der Rückenkonstruktion hergestellt | |

Produktübersicht

Produktübersicht Berufskleidung | Berufsschuhe 2024

Berufskleidung | Berufsschuhe 2024 Gesamtkatalog 2023/2024

Gesamtkatalog 2023/2024