ESD flooring - What role does ESD flooring play?

ESD floor coverings are a central component of ESD zones in accordance with IEC 61340-5-1. They are used for the controlled discharge of electrostatic charges from people, devices and moving objects via defined earthing points. The aim is to prevent the formation of dangerous potential differences that can lead to uncontrolled discharges and thus pose a risk to sensitive electronic assemblies or in explosion protection areas.

Why is an ESD floor important?

By complying with specific surface and discharge resistances (typically: 10⁴-10⁹ Ω in accordance with IEC 61340), ESD floor coverings make a significant contribution to reducing ESD risks. ESD flooring prevents people or objects from becoming charged through movement and then discharging in an uncontrolled manner. It should be noted that personal earthing only works with suitable ESD footwear.

ESD floors are used in particular in EPAs (Electrostatic Protected Areas) - for example in electronics production, the semiconductor industry or in potentially explosive zones in accordance with the ATEX directive.

We are happy to assist you with laying your new floor covering. Further information can be found here.

Benefits

- Protection of sensitive electronics: In electronics manufacturing (e.g. production of semiconductors or circuit boards), even very small discharges (from approx. 100 V) can destroy components or drastically shorten their service life.

- Prevention of failures and malfunctions: In data centres or server rooms, ESD can lead to malfunctions.

- Fulfilment of legal and normative requirements: In many industries (e.g. automotive, aviation), regulations and standards (e.g. IEC 61340-5-1) require ESD-safe work areas.

- Safety in potentially explosive atmospheres: In ATEX zones, sparks can cause dangerous explosions due to electrostatic discharges.

What are the differences between the floor coverings?

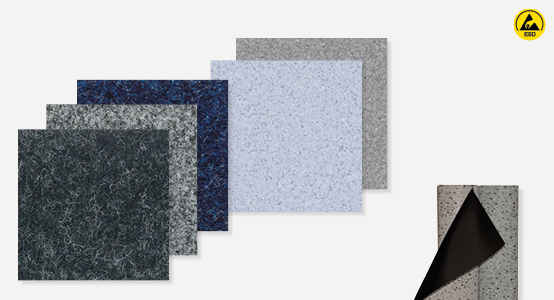

ESD roll goods and cuttings - for seamless, durable coverage

ESD roll goods are suitable for large-scale, seamless installation on a specially prepared subfloor. The roll goods can be cut to size individually and can therefore be adapted to specific spatial requirements. The floor covering is designed for permanent installation by bonding it to the subfloor.

to the products

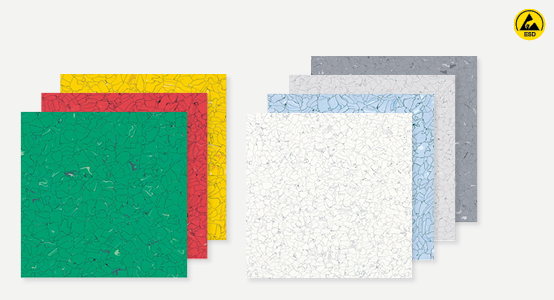

ESD tiles - easy to lay, easy to replace, limitless in design

ESD tiles are laid with adhesive. Depending on requirements, a specific pattern can be laid to visually separate areas from one another or to identify emergency exits and escape routes using signal colours. In the event of damage, the individual tile affected can be replaced, which minimises repair costs.

to the products

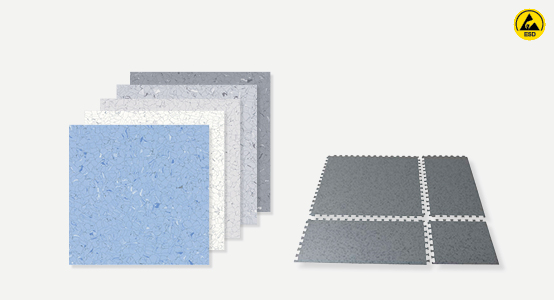

ESD Interlocking system - for simple, adhesive-free installation

The modular interlocking tiles are characterised by quick and easy installation. Thanks to the adhesive-free installation, the floor covering can be easily removed if necessary. For this reason, the flooring is suitable for temporary work areas or rental properties. In the event of damage, the individual tile affected can be replaced, minimising repair costs.

to the products

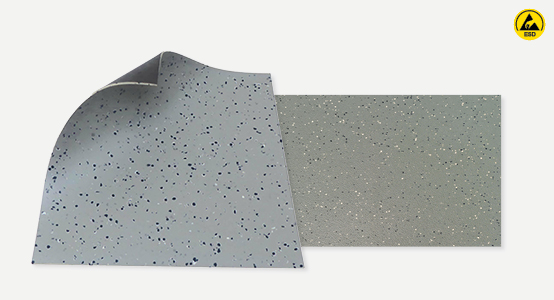

ESD mats - handy, practical, flexible

ESD mats are flexible, portable mats. They are designed for selective use. The mats can be used temporarily or permanently at the respective workstations.

to the products

Specific mats: Anti-fatigue mats - for more ergonomics and productivity

Ergonomics in the workplace promotes employee health, increases productivity and reduces absenteeism. The elastic and cushioning anti-fatigue mats stimulate blood circulation in the body, resulting in fatigue-free, joint-friendly standing.

to the products

Specific mats: Tacky mats - for particle-free cleanliness

Disposable adhesive film mats or permanent adhesive dust control mats are ideal aids for cleaning shoe soles, wheels and castors in access areas to controlled ESD zones and cleanrooms. They bind dust and particles and help to ensure compliance with hygiene regulations.

to the products

Product overview

Product overview Workwear | Professional Footwear 2024

Workwear | Professional Footwear 2024 DPV main catalog 2023 | 2024

DPV main catalog 2023 | 2024