Electrostatic floor solutions - It’s safe. Stay safe.

ESD floor coverings safely protect against electrostatic charges, which are often caused by frictional electricity in electrostatic-sensitive interiors.

Forbo Flooring offers a broad portfolio of ESD flooring solutions. The conductive and dissipative floor coverings are perfectly suited for areas of application such as server rooms, the electronics and pharmaceutical industries and petrochemical and food production facilities.

Regardless of whether electrostatically conductive or dissipative floor coverings, the material or design, the existing subfloor construction or the installation during operation without downtime: It’s safe. Stay safe.

The 7 colorex® securities

1. Future-proof - fulfils tomorrow's requirements today

2. ESD suitability over the entire service life

3. cleanroom suitability - non-porous surface with minimal outgassing behaviour

4. Decontaminability and chemical resistance

5. Universally applicable - suitable for all substrates

6. 100% repairability - surface damage can be easily repaired

7. Resilient - excellent resistance to dynamic and mechanical stresses

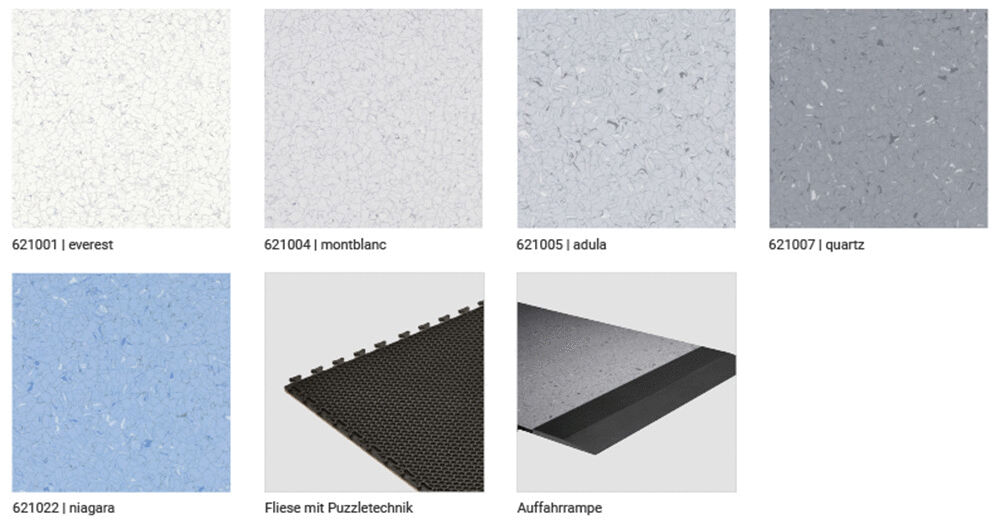

colorex® plus EC – conductive interlocking system

Colorex Plus EC for loose laying offers outstanding material properties - from permanent conductivity to the compact and non-porous Colorex surface. The individual panels are firmly bonded together using an invisible dovetail system.

Refurbishment with system and colorex® plus EC

Colorex was specially developed for demanding areas of application and is available in different product variants: Conductive and highly conductive versions are available either for permanent bonding directly to the subfloor or to raised floor constructions or as Colorex plus for loose laying. The loose lay R10 plus construction completes the extensive range of Colorex high-tech solutions.

Floor refurbishment in industrial companies is usually a cost-intensive measure. Production stoppages due to the conversion of heavy equipment and complex subfloor renovation work cost a lot of time and money even before the floor is laid. But there is another way: with Colorex Plus EC from Forbo Flooring.

Colorex Plus EC is laid loose during operation and can be walked on immediately. Thanks to the innovative honeycomb structure on the back, the flooring can be laid on problematic surfaces. The individual components are joined together by a concealed dovetail system and combine all Colorex properties, including permanent conductivity. In addition to this advantage and the ease of installation, the flooring also scores with an extremely resilient, non-porous and easily sanitised surface.

Zum Shop

colorex® EC – conductive vinyl

Colorex EC is the highly conductive solution for maximum safety when avoiding electrostatic charges and fulfils the latest international standards. The floor covering has an earth leakage resistance of 5 x 104 -1 x 106 Ω and is suitable for grounding people via the man-shoe-floor system (IEC 61340-4-5) to protect electronic components and equipment from personal discharges. Colorex EC is particularly suitable for ESD areas, operating theatres/intensive care units, clean rooms, explosion-proof rooms and for use in the electrical and pharmaceutical industries.

Find out nowcolorex® SD – dissipative vinyl

Colorex SD has an earth leakage resistance of 1 x 106 - 1 x 108 Ω and is ideal for areas where electrostatic charges can arise and must be safely discharged. Colorex SD also fulfils the dual requirement: it is both dissipative and insulating in accordance with VDE 0100-600 to protect people who are exposed to hazards when coming into contact with live parts (< 500 V). The high-tech vinyl flooring is particularly suitable for new laboratories, radiological areas, for use in the electrical and pharmaceutical industries and in battery rooms

Learn moreChoose the right flooring solution

Tile | Tile (interlocking system) | Tile | |

Electrical properties | conductive | conductive | dissipative |

Classification EN ISO 10874 Commercial use - class 34 very strong |  |  |  |

Classification EN ISO 10874 Industrial use - Class 43 strong |  |  |  |

Forklift suitability |  |  |  |

Lift truck suitability |  |  |  |

Raised floor suitability |  |  |  |

Extreme chemical resistance |  |  |  |

Decontaminability |  |  |  |

Cleanroom approval |  |  |  |

Requirement according to VDE 0100 |  | ||

Battery space requirement |  | ||

Fire behavior EN 13501-1 | Bfl-s1, G, CS | Bfl-s1, L, CS | Bfl-s1, G, CS |

Article overview

Product overview

Product overview Workwear | Professional Footwear 2024

Workwear | Professional Footwear 2024 DPV main catalog 2023 | 2024

DPV main catalog 2023 | 2024