Product Family

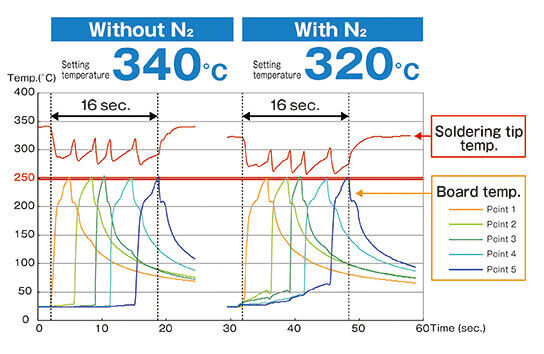

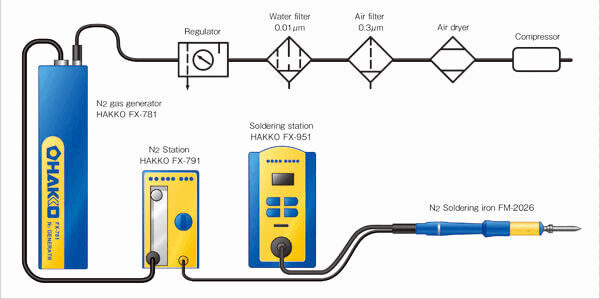

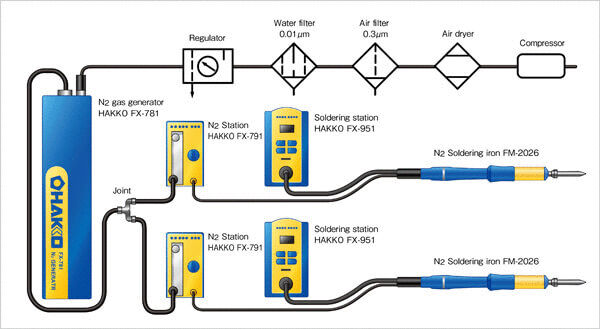

HAKKO N2 system

Article image

Article description

Height

Length

Width

Weight

Price

Compare

Product overview

Product overview Workwear | Professional Footwear 2024

Workwear | Professional Footwear 2024 DPV main catalog 2023 | 2024

DPV main catalog 2023 | 2024