PCB magazines 6000 and 7000 – Precision deployment

ESD PCB magazines enable the safe transport and electrostatic-protected storage of printed circuit boards in sensitive areas of electronics manufacturing.

The magazines are compatible with automated assembly processes and can be easily integrated into existing production lines. They are designed for different types and formats of printed circuit boards and promote structured material provision and efficient production logistics.

All magazines are available in the following materials for the side walls and can be purchased fully or partially assembled:

The magazines are compatible with automated assembly processes and can be easily integrated into existing production lines. They are designed for different types and formats of printed circuit boards and promote structured material provision and efficient production logistics.

All magazines are available in the following materials for the side walls and can be purchased fully or partially assembled:

- Polystyrene (PS): Heat resistance up to 60 or 50 degrees (temperature of the inserts or the environment)

- Polycarbonate (PC): Heat resistance up to 130 or 80 degrees (temperature of the inserts or the environment)

- Metal: Heat resistance up to 200 degrees Celsius (temperature of the inserts or the environment)

The advantages at a glance

Why are cab PCB magazines a particularly good choice?

cab PCB magazines are more than just standard storage solutions – they are precise, durable, and designed for production to meet the modern requirements of electronics manufacturing.

- Maximum protection for sensitive printed circuit boards

- Optimized production processes through automation

- Time and cost savings through fast loading and unloading

- High flexibility for different PCB formats

- Clean, structured production instead of chaotic temporary storage

What are the benefits of the new series?

Unlike their predecessors, the new 6000 and 7000 series feature completely closed cover and base plates. Finally, nothing can penetrate from above or below, ensuring greater rigidity.

6000 series

Offers cost-effective, manual width adjustment via screw clamps – ideal for standard processes with less frequent format changes.

Offers cost-effective, manual width adjustment via screw clamps – ideal for standard processes with less frequent format changes.

7000 series

Features faster, more precise adjustment options, either via toothed belt or even motorized, making it particularly flexible for automated lines and frequent format changes.

Features faster, more precise adjustment options, either via toothed belt or even motorized, making it particularly flexible for automated lines and frequent format changes.

PCB magazines 6000 series

The 6000 series PCB magazines are the successors to the previous 600 series. The width is adjusted manually by moving the crossbar and securing it with the screw clamps. The 6000 series is a more cost-effective option.

1. To protect the circuit boards, the cover plates and base plates are completely closed except for the guide grooves.

Nothing can penetrate from above or below, and greater rigidity is ensured.

Nothing can penetrate from above or below, and greater rigidity is ensured.

2. Securing printed circuit boards during transport

Type B transport locks are included separately with partially assembled magazines. Type A or C locks can also be ordered as an option.

Type B transport locks are included separately with partially assembled magazines. Type A or C locks can also be ordered as an option.

3. Adjusting to the PCB width

The web can be adjusted to the desired PCB width by loosening the four screw terminals..

Detailed information and all modelsThe web can be adjusted to the desired PCB width by loosening the four screw terminals..

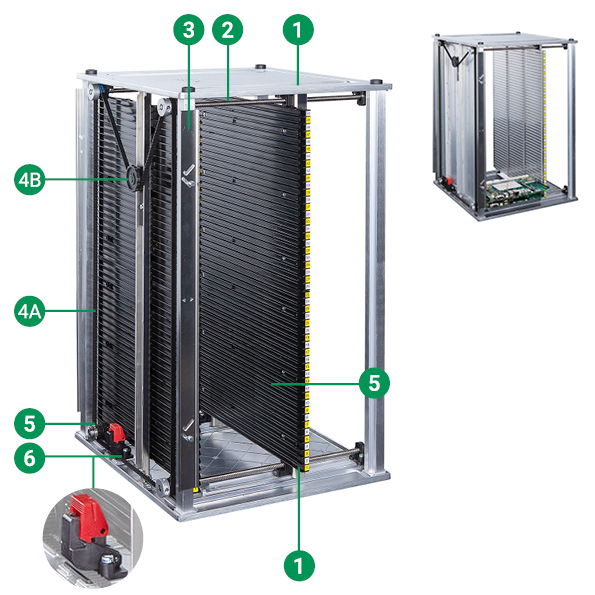

PCB magazines 7000 series

The 7000 series PCB magazines are a logical further development of the previous 700 + 800 series. The width is adjusted manually on the toothed belt (Fast Lock) or motorized on the coupling.

1. The cover plates and base plates are completely closed to protect the circuit boards.

Nothing can penetrate from above or below, and greater rigidity is ensured.

Nothing can penetrate from above or below, and greater rigidity is ensured.

2. Synchronous adjustment of the web wall

With four precision spindles and backlash-free bearings, the PCB width can be adjusted quickly and accurately.

With four precision spindles and backlash-free bearings, the PCB width can be adjusted quickly and accurately.

3. Securing printed circuit boards during transport

Type A transport locks are included separately with partially assembled magazines. Type B or Type C locks can also be ordered as an option.

Type A transport locks are included separately with partially assembled magazines. Type B or Type C locks can also be ordered as an option.

4. Adjust to the circuit board width manually

4A by pulling on the toothed belt

4B Fine adjustment by turning the handwheel

4A by pulling on the toothed belt

4B Fine adjustment by turning the handwheel

5. Motorized adjustment to the PCB width at the coupling

Once the magazine is positioned in the unloader, the servomotor is connected to the spindle gear via a coupling.

Once the magazine is positioned in the unloader, the servomotor is connected to the spindle gear via a coupling.

6. Fixing the width setting

The toothed belt is fixed in place using a fastlock (quick-release fastener). When adjusting to the PCB width manually, the clamping block is lifted by pressing it and locks into place. Pressing the locking lever fixes the toothed belt in place again. When adjusting the width using a motor, the clamping block is lifted during the positioning process using a tappet.

Detailed information and all modelsThe toothed belt is fixed in place using a fastlock (quick-release fastener). When adjusting to the PCB width manually, the clamping block is lifted by pressing it and locks into place. Pressing the locking lever fixes the toothed belt in place again. When adjusting the width using a motor, the clamping block is lifted during the positioning process using a tappet.

Special magazines for the 6000 and 7000 series

Special models with double capacities or lower heights are available on request – our sales team will be happy to advise you.

Double capacity thanks to parallel insertion for magazine series 6000

For up to 100 printed circuit boards in one magazine.

For narrow printed circuit boards, magazines with two inserts can be used side by side.

Low height for magazine series 6000, 7000

Low-height PCB magazines, e.g., for use in tempering ovens. Reducing the height also prevents weight overload with heavy PCBs or the use of product carriers.

Product overview

Product overview Workwear | Professional Footwear 2024

Workwear | Professional Footwear 2024 DPV main catalog 2023 | 2024

DPV main catalog 2023 | 2024